How Diamon-Fusion® Nano-Technology Works

Proven Science. Powerful Protection.

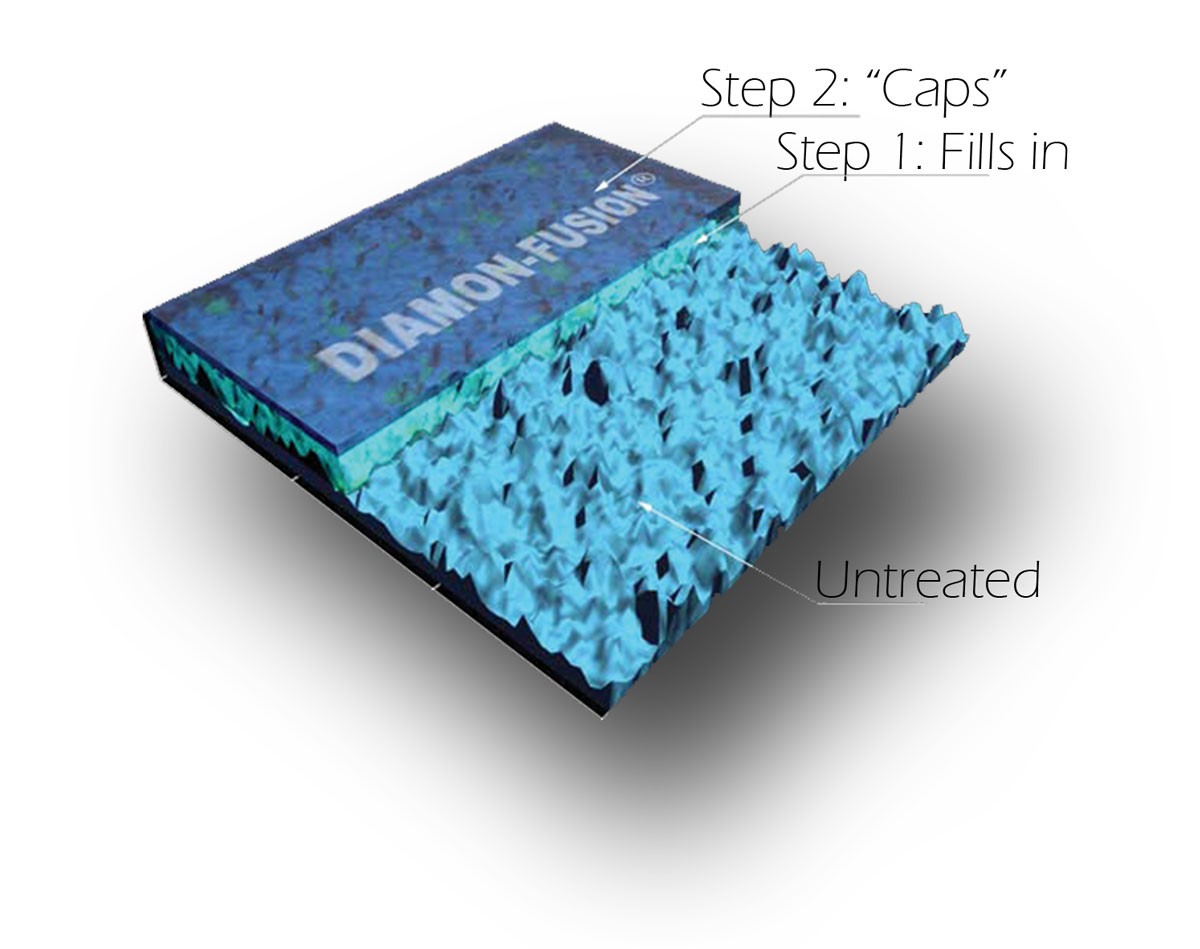

Diamon-Fusion® is a patented glass treatment technology that dramatically improves the durability, clarity, and cleanability of glass and other silica-based surfaces. Developed through advanced nano-chemistry and tested by leading experts in the field, this two-stage process creates an invisible barrier that protects glass from water, staining, scratching, and impact damage.

The Two-Stage Protective Process

Stage 1: Molecular Bonding

The first step creates a “cross-linked and branched” nanofilm that grows outward from within the glass surface. This molecular bonding forms the foundation of Diamon-Fusion®'s long-term durability and performance.

Stage 2: Surface Capping

The second step “caps” the molecular chain, sealing the surface and dramatically increasing its hydrophobic properties. This makes the glass highly water-repellent, stain-resistant, and smooth—preventing contaminants from bonding with the surface.

- No curing time required

- All chemicals become inert within seconds

- Process completes in under 2 seconds

Nanotechnology at Work

This process, known as nano-chemistry, operates at a microscopic scale—approximately 1 to 100 nanometers. At this level, Diamon-Fusion® forms a nanostructured layer that is optically clear, highly durable, and chemically fused to the glass.

The Strength of Covalent Bonding

Diamon-Fusion® is not a simple surface coating—it’s covalently bonded to the glass. That means the molecules of the coating share electrons with the molecules in the glass itself, becoming part of the surface. Covalent bonds are up to 10 times stronger than hydrogen-bridge bonds used in most other water-repellent coatings.

Independent Test Results

Conducted by Dr. William C. LaCourse

Professor of Glass Science at Alfred University (Institute for Glass Science and Engineering)

Dr. LaCourse’s independent testing of Diamon-Fusion® showed impressive results in both surface friction reduction and scratch resistance, especially under wet conditions—when glass is most vulnerable to damage.

Water Repellency – Contact Angle Comparison

| Material | Contact Angle (°) | |

|---|---|---|

| Untreated Glass | 14° |  |

| Treated with DF1 | 90° |  |

| Treated with DF2 | 118° |  |

Higher angles indicate greater water repellency.

Scratch & Impact Resistance – Coefficient of Friction (Wet)

| Material | Coefficient (μ) |

|---|---|

| Untreated Glass | 0.82 |

| Diamon-Fusion® Treated | 0.13 |

This friction reduction translates directly to impact resistance.

Load Required to Damage Glass

| Material | Load (lbs) |

|---|---|

| Untreated Glass | 0.37 lbs |

| Diamon-Fusion® Treated | 4.00 lbs |

Result: Treated glass requires over 11.76x more force to crack or scratch compared to untreated glass.

In practical terms, a debris particle would need to weigh 10 times more to damage Diamon-Fusion®-treated glass versus untreated glass.

Real-World Performance

- Reduces rock chip damage from road debris

- Makes glass 10x harder to scratch

- Improves clarity and visibility

- Extends the lifespan of glass installations

Ready to See the Science in Action?

Diamon-Fusion® is a globally proven solution applied on everything from shower doors to windshields, skyscrapers to solar panels. The science is real—and so are the results.

Contact us today to learn more or schedule an application for your residential, commercial, or automotive glass.